Data is the new oil.

In the sense that both make the world go round, perhaps so. The two, however, are not without contrasts.

Oil is scarce, data is practically infinite; oil starts as crude, raw data comes in different forms; reusing oil is deemed inexpedient, data is all about repurposing. So forth, so on.

The biggest difference of all? Data isn’t terrestrial. Terabytes of information flow through the sky with each passing second.

Now, that leads us to the elephant in the room – how’s all that aerial data managed?

The answer lies in drone analytics.

What is Drone Data?

As far as semantics is concerned, drone data is as straightforward as it gets. It simply refers to aerial information collected by drones. But that’s a loose definition that fails to capture its extensive breadth and utility.

To truly understand the multilayered nature of drone data, one must first look at different types and grasp how they’re applied under various commercial contexts.

Data Collection Using Drones

Imaging

Humans have pain receptors that fire up the nerves when something goes wrong. Infrastructure assets are bereft of such self-preserving mechanisms. The only way to tell whether assets are defect-free is by giving them a close-up look.

Unfortunately, doing so is no cakewalk. Take wind turbines, for example. It takes hours for a group of rope access technicians to work their way down, squinting at or knocking on the blade to see if it’s sound and whole. Inspecting assets this way is counterproductive, error-prone, and precarious at best.

An alternative? Drone photography.

Namely, highly autonomous solutions such as NearthWIND Pro and Mobile take no more than 15 minutes to collect thousands of images with high-resolution cameras across the surface area, which, in turn, can be used to identify the precise location of the defects.

Photogrammetry

Not a way of collecting data per se, but we’d be remiss not to touch on photogrammetry. After all, drone mapping would still be stuck in a two-dimensional realm had it not been for photogrammetry.

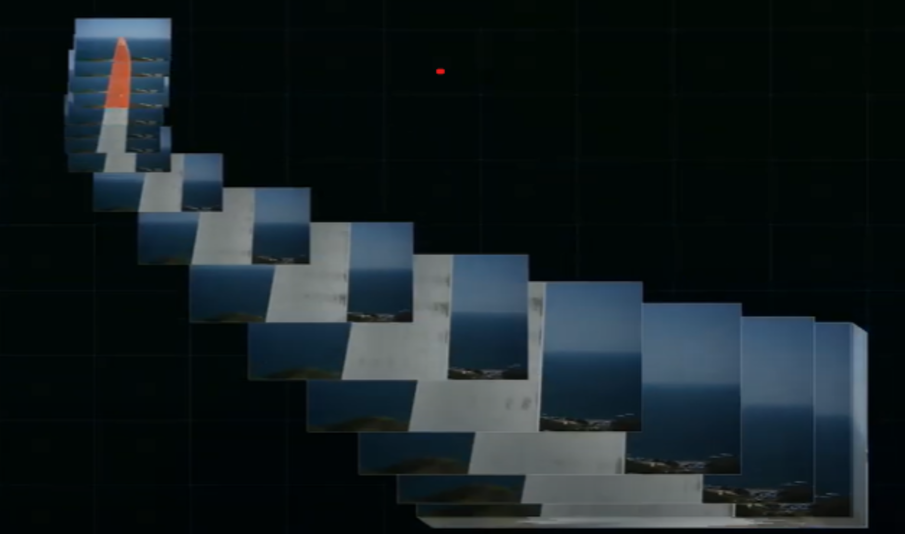

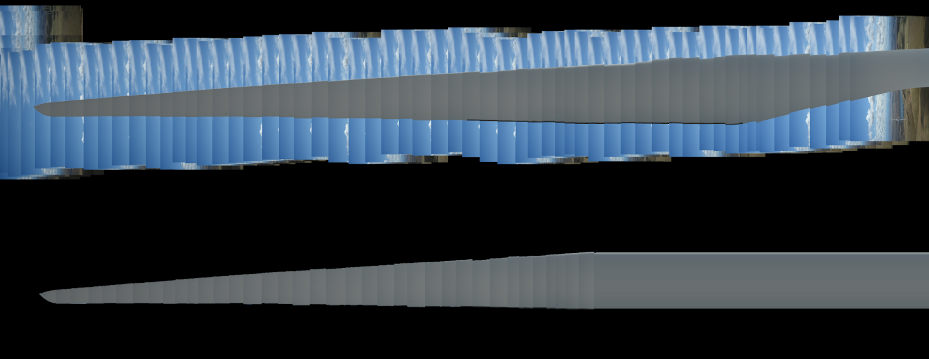

One way to think of photogrammetry is as photography’s overachieving brother. Once aerial images are compiled, photogrammetry takes a step further to stitch the images together into a three-dimensional rendering. The value of the resulting model is proving to be immense as it provides a holistic view of the asset from all angles and ranges.

LiDAR

There are different ways to go about 3D mapping. Of them is light detection and ranging, better known as LiDAR.

The building blocks of LiDAR-driven 3D models are lasers. Or, to be precise, the data points lasers yield.

A typical LiDAR survey goes as follows:

- The transmitter shoots out pulses of light at a target.

- The receiver records the angle, intensity, and timing of the reflected pulses.

- The resulting dataset forms point clouds that are remolded into a 3D rendering.

Despite its next-level geospatial accuracy, LiDAR falls short when it comes to photographic depth. Plus, the hefty price tag that comes with LiDAR sensors may not make up for the most budget-conscious move, particularly when photogrammetry is available.

Thermal Detection

Sometimes, one must look past visual cues to ensure the asset is in good standing. Indicator industries can resort to in those instances is heat.

By measuring the spectrum of infrared frequencies using microbolometers mounted on a gimbal, thermal drones put heat gaps spread across the asset on full display to help detect freezes, leaks, and other conditions that could make or break operations and maintenance (O&M).

However, the effectiveness of thermal drones is limited by certain factors such as windy, humid climates and flight speed.

Sampling

Lubricants quite literally grease the wheels of industrial operations. Ensuring it stays that way often turns out to be an uphill battle, as the sump is typically located in areas that are difficult to reach physically. Worse yet, manual sampling comes with the risk of stirring up the debris sitting down under, rendering the entire process meaningless.

With the recent improvements in drone technology, sampling is no longer much of a hassle. Equipped with a payload comprised of ultrasonic rangers, vials, and pumps, drones are increasingly proving their worth within the sampling sphere.

Data Science with Drones

Now that we’ve brushed up on drone data let’s get down to the nuts and bolts.

Data analytics is an umbrella term for processes and systems behind turning unstructured data into actionable insights. Drone analytics is exactly that but with aerial data.

Drone Analytics Workflows

The steps drone data goes through may seem virtually identical in the grand scheme of things. But not all analytics workflows are made equal.

For the sake of a crisp, concise overview, we’ll base the rest of the rundown on drone imagery, the most prominent aerial mapping technique out there today.

Image Processing

Preprocessing

As accurate and detailed as drone imaging is, too many factors are at play for images to appear consistent in their raw state. A slight shift in background intensity can lead to a visible change in contrast and resolution.

To ensure that the final product turns out blemish-free, the value of individual pixels must be modified so that each image looks clean and uniform in terms of orientation, ratio, size, and more.

Post-Processing

Once the dataset has been standardized, it’s due for post-processing.

The reasons to run images through an additional round of processing are twofold.

- Getting rid of the guesswork

Referring to the final product imprinted on the box is tabooed amongst avid puzzle solvers. That’s because having access to a holistic view makes it much easier to determine where an individual piece falls on the jigsaw. Defect identification is no different. With access to a panoramic view, tracking down the defects becomes a matter of observation, not intuition.

- Preventing missing data from going unnoticed

Looked at in a vacuum, it’s impossible to tell whether the drone has covered every bit of the asset. From a bird’s eye view, on the other hand, missing parts are bound to stick out like a sore thumb.

Data Analysis

Images have been stitched together into a clean-cut composite. All there’s left is to take a crack at defect marking, though working your way through might turn out to be a handful.

That goes for even the most trained set of analysts. There’s only so much the naked eye can do to dig up defects that may as well be the size of a bug bite.

Thankfully, we no longer have to bank on human optics. With artificial intelligence at our disposal, dedicated software solutions can do the work instead.

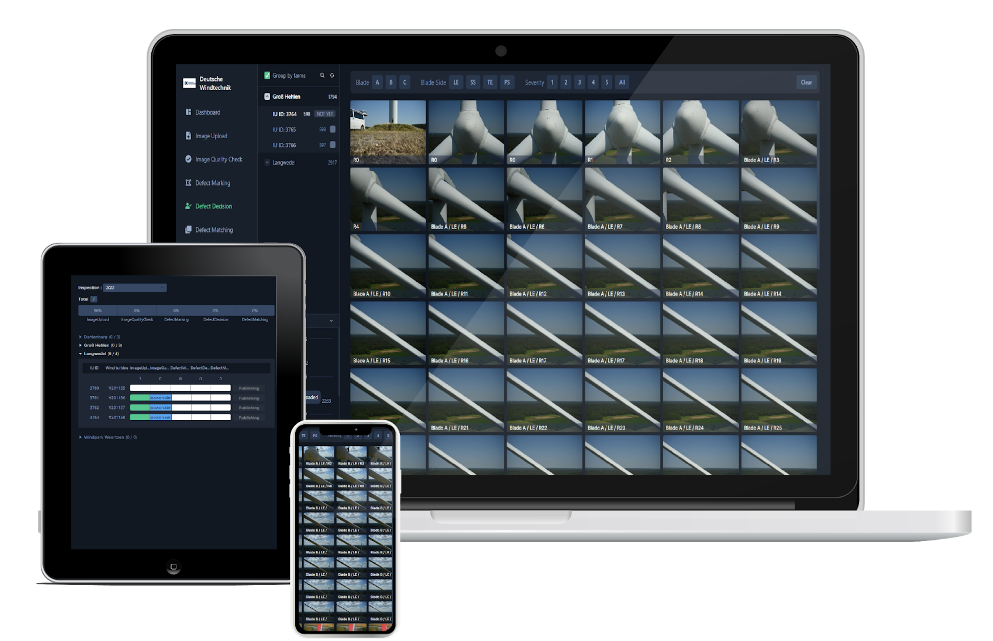

Of course, no solution is perfect. But had there been a one-size-fits-all drone analytics software, it’d look very much like Zoomable. Before giving you our two cents on why that is, spare us a second to brush over reporting - the final phase of the analytics process.

Reporting

The importance of reporting cannot be overstated. Insights are hardly any good kept all to yourself. Only after getting the stakeholders on the same page through proper data sharing can you start to make more informed decisions.

Done manually, however, reporting can be an incredibly monotonous process. Plus, time is too valuable of a commodity for anyone to waste hours on end crunching numbers into a spreadsheet.

Opting for reporting automation tools could be an option. But most come without the ability to integrate with other software applications natively. It’ll be up to you to update the data from the backend with each report.

Now, what if we told you there’s a way to automate the entire analytics workflow? From pre and post-processing to defect detection and reporting automation. Sounds too good to be true, right?

Well, not necessarily.

Meet Zoomable.

As an end-to-end solution, Zoomable takes the dataset through rounds of processing to give the images a clean polish before stitching them together into a coherent composite. Defects are then sorted out according to type and severity.

From there, Zoomable cross-references the identified defects with historical data to come up with estimated cost and repair time. As a cherry on top, all relevant information is compiled into a customizable report.

Drone Analytics Market Trends

Zoomable is a prime example of a blue ocean strategy gone right. Much of its success owes to the shrewd foresight of developers who sought to put forward an end-to-end solution before the ever-rising adoption of UAV technology turned drone analytics into a hotbed for competition and innovation.

Now that virtually every industry – agriculture, construction, and site inspection, among others – has come around to using UAVs to collect data and perform tasks once thought unimaginable, the demand for drone analytics solutions is taking off like never before.

The numbers say it all. The latest research from Allied Market Research shows that the market size of the global drone analytics industry, currently valued at $2.7 billion, is expected to more than tenfold before the turn of the decade at an impressive CAGR (compound annual growth rate) of 29.2 percent.

The Future of Drone Data and Artificial Intelligence

Technological advancements in machine learning, dubbed with heightening interest and investment in drone services from leading companies and small enterprises, are pushing the boundaries of drone operations.

The government, too, is doing its part by easing regulations and devising frameworks to accommodate a symbiotic environment where key players continue to thrive while new entrants follow in the footsteps of leading players.

With public and private sectors working together to bring about the next wave of the industrial revolution led by autonomous drones, organizations that learn to embrace drone analytics will be able to navigate the growing sea of aerial data to stay well ahead of the curve.